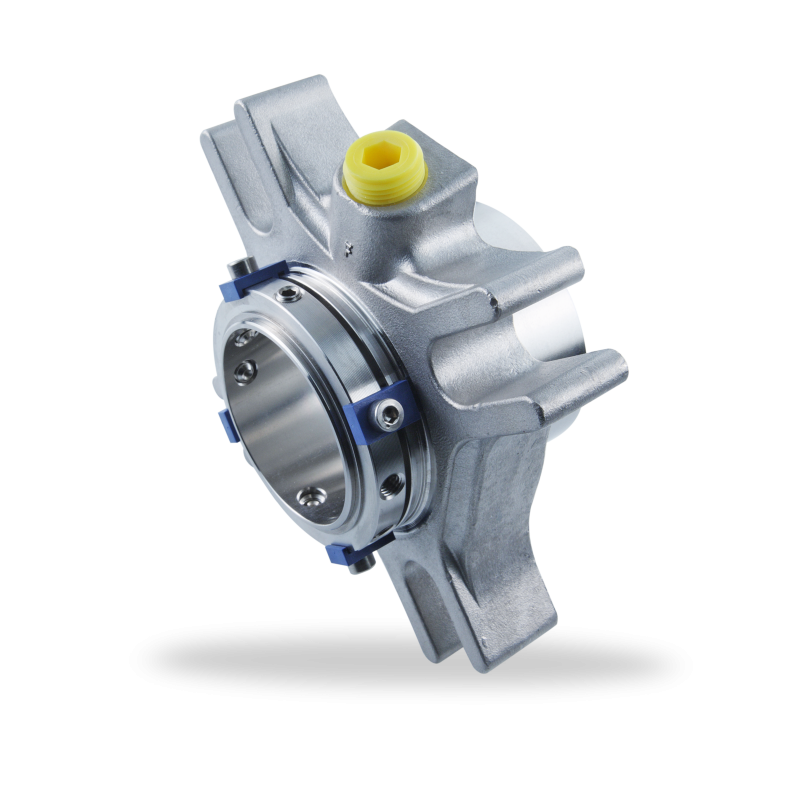

Cartex Dual seals

Cartex Dual seals

Category:

Pumps and valves

This product is provided by the company EAGLEBURGMANN ENDÜSTRİYEL SIZDIRMAZLIK SAN.VE TİC.LTD.ŞTİ. . Please contact for more information.

Product Description

Features

Dual seal

Cartridge

Balanced

Independent of direction of rotation

Double pressure balanced

Integrated pumping device

Variants available: for eccentric screw pumps (-Vario) and gas-lubricated version (-GSDN)

Advantages

Ideal seal for standardizations

Universal applicable for packings conversions, retrofits or OEM

No dimensional modification of the seal chamber (centrifugal pumps) necessary, small radial installation height

No damage of the shaft by dynamically loaded O-Ring

Extended service life

No damage caused by dirt entered during assembly

Straightforward and easy installation due to pre-assembled unit

Individual adaptation to pump design possible

Customer specific versions available

Operating range

Shaft diameter:

d1 = 25 ... 100 mm (1.000" ... 4.000"

Other sizes on request

Temperature:

t= -40 °C ... 220 °C (-40 °F ... 428 °F)

(Check O-Ring resistance)

Sliding face material combination BQ1

Pressure: p1 = 25 bar (363 PSI)

Sliding velocity: vg = 16 m/s (52 ft/s)

Sliding face material combination Q1Q1 or U2Q1

Pressure: p1 = 20 bar (290 PSI)

Sliding velocity: vg = 10 m/s (33 ft/s)

Barrier fluid circulation system:

p3max = 25 bar (363 PSI)

?p (p3 - p1)ideal = 2 ... 3 bar (29 ... 44 PSI),

7 bar (102 PSI) for barrier media with poor lubricating properties.

Pump startup:

?p (p3 - p1)max = 25 bar (363 PSI) allowed

Recommended supply medium:

max. ISO VG 5

Axial movement: ±1.0 mm, d1 ?75 mm ±1.5 mm

Materials

Seal face: Silicon carbide (Q1), Carbon graphite resin impregnated (B), Tungsten carbide (U2)

Seat: Silicon carbide (Q1)

Secondary seals: FKM (V), EPDM (E), FFKM (K), Perfluorocarbon rubber/PTFE (U1)

Springs: Hastelloy® C-4 (M)

Metal parts: CrNiMo steel (G), CrNiMo cast steel (G)

Standards and approvals

Compliant to TA Luft (German Clean Air Act)

Recommended applications

Petrochemical industry

Chemical industry

Pharmaceutical industry

Power plant technology

Pulp and paper industry

Mining industry

Food and beverage industry

Sugar industry

CCUS

Lithium

Hydrogen

Sustainable plastics production

Alternative fuels production

Power generation

Nuclear power technology

Universally applicable

Centrifugal pumps

Eccentric screw pumps

Recommended piping plans

The EagleBurgmann QFT1000 buffer system and QFT2000 vessels are suitable for Cartex-DN in back-to-back arrangement. The EagleBurgmann TS1016 and TS2000 thermosiphon systems support double and back-to-back seal configurations.

Product links:

EagleBurgmann QFT1000

EagleBurgmann QFT2000

EagleBurgmann TS1000

EagleBurgmann TS2000

EagleBurgmann MultiFlow Unit (MFU)

EagleBurgmann BestFlow

Other Products of the Company

See AllSimilar Products

See AllLubrication System Components

Lubrication System Components

LIQUID RING VACUUM PUMPS

ECO-SYS Liquid Ring Vacuum System

Pump