| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

YESTİ İNŞAAT VE TİC. LTD. ŞTİ.

Helis Gold Ofis Yeşilbağlar Mah. Dumanlar Sok. No: 1 Kat: 4 34893 / Pendik / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 392 3343

|

Hall: 7

Stand: 733D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Yesti was founded in 1992 by E. Murat PEKEL. In the 30 years since, we have created a great team of colleagues, most of whom have been working with us for more than twenty years, and we have taken part in many prestigious projects at home and abroad with our long years of experience and had the opportunity to cooperate with many respected and valuable companies. We can list our main fields of activity as follows Geosynthetics & Environmental Projects Construction (Reinforced Concrete & Steel Works) Prefabricated and Container Building Works Thanks to our solution- and customer-oriented approach and our understanding of teamwork, Yesti Group has succeeded in establishing long-term relationships with its customers and has implemented quality projects safely and within the stipulated budget. Thus, Yesti has become a company that serves on three continents today. As a result of spreading to wide geographies, Yesti opened a branch in Burkina Faso, Africa in April 2022, thus accelerating the operational processes in its overseas projects and providing a more effective business management. Our primary goal is to prevent the pollution of air, water and soil in line with our understanding of putting the environment first and our philosophy of respect for nature since the day Yesti was founded. For this purpose, we comply with the environmental legislation and administrative regulations, use environmentally friendly building materials in all our production processes, ensure that all our employees, suppliers and subcontractors reach environmental awareness by constantly auditing the environmental management system we apply, and we work hard to pass down a livable environment to new generations by carrying out the necessary trainings in this direction. We are happy to announce that we have been awarded the following certificates in international standards as well as local certificates, which are a testament to our commitment to sustainability ISO 9001 Quality Management System ISO 14001 Environmental Management System ISO 45001 Occupational Health and Safety Management System TÜV SÜD Plastic Welder Certificate While we strive to go beyond our customers expectations with our expertise and our dedication to innovation, quality and integrity, we will be pleased to offer you tailored and unique solutions.

Geomembrane is a polymer (HDPE/LLDPE) material provides a barrier function to protect the environment ( water, soil, and air) and to contain liquids and gases. Various types of polymeric geomembrane barriers exist for demanding applications from mining and any class of landfill to petrochemical, oil and gas industries, thermal power industries, agriculture and aquaculture. Thickness Values (mm): 0,75 1,00 1,50 2,00 2,50 3,00 Characteristic Advantages; High impermeability High chemical resistance High mechanic resistance Extremely Durable High UV resistance Installation Areas; Mine Heap Leach Facilities Mine Tailing Storage Facilities Mining Solution Ponds Sediment Ponds Landfills Ash Monofil Hazardous Waste Landfills Hazardous Waste Storage Ponds Thermal Power and Bioenergy Facilities Oil and Petrochemistry Facilities Sewage Threatment Facility Sewage Lagoons Evaporation and Brine Ponds Agriculture Ponds Aquaculture Ponds Building Foundation Waterproofing Water Canals Tunnels Artificial Ponds Fire Supression Ponds

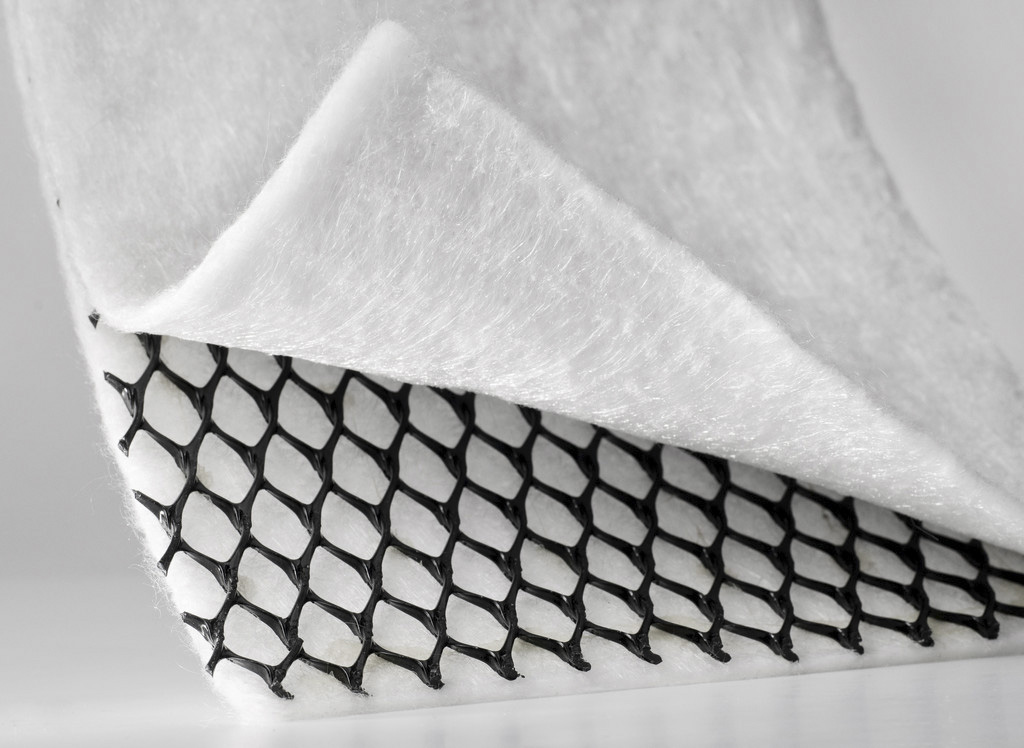

Geotextiles are divided into two according to the production technique; Nonwoven Geotextiles:It is a nonwoven (manufactured from unidirectional or randomly arranged fibers) layer, net or felt, in which polyester and/or polypropylene fibers are combined by needle punching method in order to provide economical and permanent solutions in civil engineering and especially soil mechanic problems. It is the most commonly preferred type of geotextile. Woven Geotextiles:They are woven geotextiles used when high tensile strength is required. Woven geotextiles produced from various polymer materials (polypropylene, polyester, etc.) show high strength at low elongations, as they are produced by utilizing all the technical advantages of yarn. Even though the yarns are woven in two directions at right angles to each other, the material exhibits significant diagonal strength due to friction and winding between the yarns. Functions; 1. Reinforcement: Thanks to its high resistance and high friction coefficient on the earth layer, by taking a portion of the load on the soil on itself, it provides a more uniform weight distribution over the surface. Thus, deformations as dispersion, cracking, and collapse are prevented. 2. Separation: As a result of the continuity, flexibility, permeability, and resistance to high tensile forces, geotextiles separate two soil layers with different geotechnical properties without interfering with the natural circulation of water. 3. Protection: Geotextile provides the desired protection on the material by reducing or spreading the deformation and stress. 4. Filtration: Geotextile allows the passage of water and prevents the passage and dragging of the soil with the smallest grain diameter. Thus, it acts as a filter. 5. Drainage: The geotextile transmits the liquid or gas along its plane to the desired outlet, especially when they are porous and provide sufficient slope. During this transmission, the liquid or gas is collected within the geotextile and transferred within its own plane. Application Areas; Building Foundation Waterproofing Road and Highways, Bridges, Viaducts Tunnels and Railways Engineering Structures Sport Arenas Parking Areas Airports Mine Heap Leach Facilities Mine Tailing Storage Facilities Mining Solution Ponds Sediment Ponds Landfills Ash Monofil Hazardous Waste Landfills Hazardous Waste Storage Ponds Thermal Power and Bioenergy Facilities Oil and Petrochemistry Facilities Sewage Treatment Facility Sewage Lagoons Evaporation and Brine Ponds Agriculture Ponds Aquaculture Ponds Water Canals Infrastructure Artificial Ponds Swamp Rehabilitation Works Fire Supression Ponds

Geonet is a double (bi-planar) or tri-planar (tri-planar) polymeric drainage network material, specially formed to ensure uniform passage of liquids and gases between various geosynthetic materials or layers under various site conditions and thickness requirements. Application Areas; Mining Solution Ponds Building Foundations Road and Highways, Bridges, Viaducts Tunnels and Railways Rock Slopes Ground Slopes Behind Retaining Walls Frost-Sensitive Floors Erosion Areas Sport Areas

It is a geosynthetic product consisting of conductive meshes placed between two geotextiles. Conductive geotextile should be used in projects where subgrade below geomembrane has insuficiently conductive properties and integrity testing (Arc testing or MIT) of geomembrane is going to be performed. Application Areas; Mine Heap Leach Facilities Mining Solution Ponds Hazardous Waste Storage Ponds

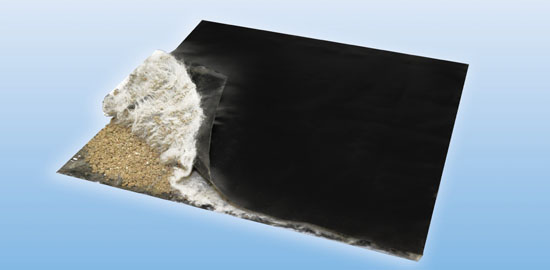

GCL (geosynthetic clay liner) is a geocomposite hydraulic barrier formed by placing low permeability sodium bentonite material between woven or non-woven geotextiles. GCL can be used as a standalone alternative to a compacted clay layer or in addition to a geomembrane lining system. Thanks to its low permeability and high shear strength, it provides long-term durability in tough conditions. Application Areas; Building Foundation Waterproofing Road and Highways, Bridges, Viaducts Tunnels and Railways Engineering Structures Sport Arenas Parking Areas Airports Mine Heap Leach Facilities Mine Tailing Storage Facilities Mining Solution Ponds Sediment Ponds Landfills Ash Monofil Hazardous Waste Landfills Hazardous Waste Storage Ponds Thermal Power and Bioenergy Facilities Oil and Petrochemistry Facilities Sewage Treatment Facility Sewage Lagoons Evaporation and Brine Ponds Agriculture Ponds Aquaculture Ponds Water Canals Infrastructure Artificial Ponds Fire Supression Ponds Swamp Rehabilitation Works

Laminated GCL is a product specially designed for liquid insulation applications by compacting geomembrane and GCL. It provides superior hydraulic performance and puncture resistance compared to other lining materials. Application Areas; Building Foundation Waterproofing Road and Highways, Bridges, Viaducts Tunnels and Railways Engineering Structures Sport Arenas Parking Areas Airports Mine Heap Leach Facilities Mine Tailing Storage Facilities Mining Solution Ponds Sediment Ponds Landfills Ash Monofil Hazardous Waste Landfills Hazardous Waste Storage Ponds Thermal Power and Bioenergy Facilities Oil and Petrochemistry Facilities Sewage Treatment Facility Sewage Lagoons Evaporation and Brine Ponds Agriculture Ponds Aquaculture Ponds Water Canals Infrastructure Artificial Ponds Swamp Rehabilitation Works

Geocomposites, which have a wide variety of types, are composite materials that are formed by laminating a geotextile to one or both sides of the geonet and are generally used for drainage, filtration, and protection purposes. It is designed as an economical alternative to conventional open-graded aggregate and/or perforated pipe underground drainage systems, both in terms of labor and material cost. Application Areas; Leachate Collection Layers Gas Venting or Leak Detection Layers Groundwater Suppression Layers Ground and Embakment Drainage Erosion Areas Building Foundation Road and Highways, Bridges, Viaducts Tunnels and Railways Sport Arenas Retaining Walls Mine Heap Leach Facilities Mine Tailing Storage Facilities Mining Solution Ponds Landfills Artificial Ponds Rehabilitation Works

Geogrid is the material used to increase the bearing capacity of the ground by taking on the tensile forces or to stabilize the ground. Application Areas; Ground Reinforcement Works Ground Stabilization Works Retaining Wall Reinforcement Works

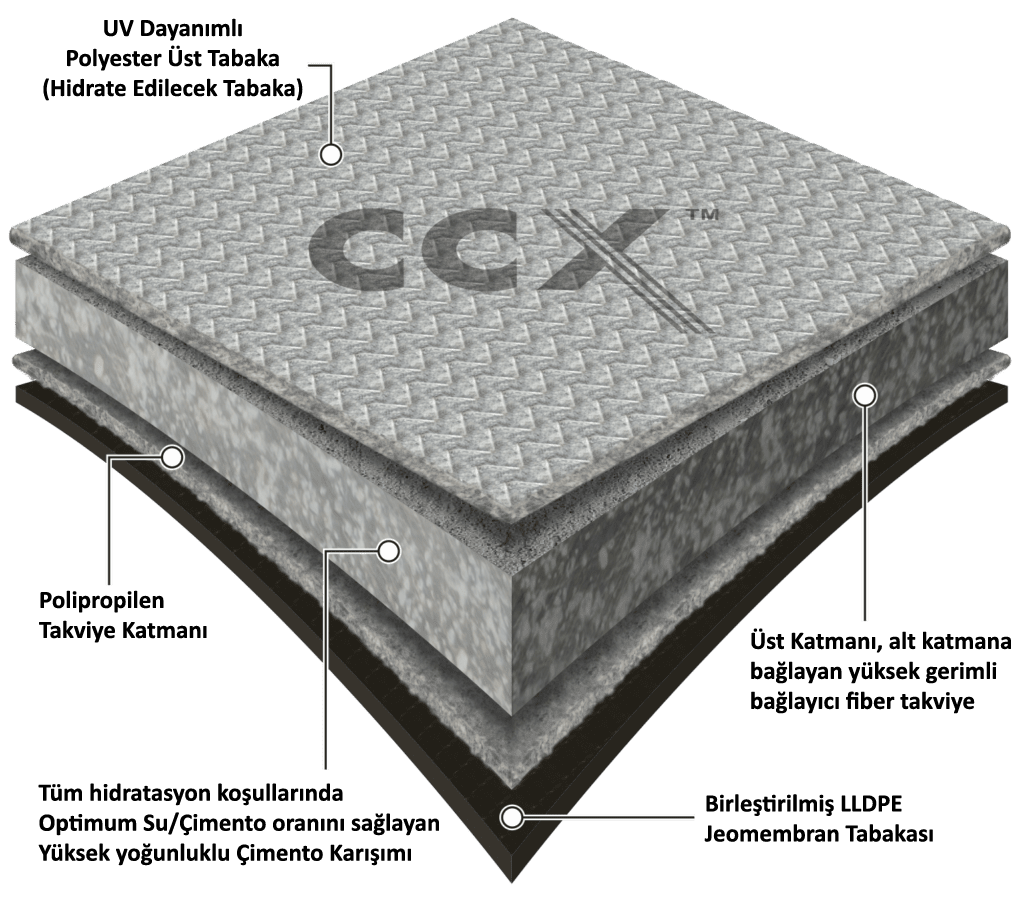

Created specifically for erosion control, containment and shelter applications, Concrete canvas products are part of a revolutionary class of new, innovative materials called Geosynthetic Cementitious Composite Mats (GCCMs). Concrete canvas is a flexible, concrete filled geosynthetic which provides a thin and durable concrete layer when hydrated. Typically, installation is 10-times faster than conventional concrete solutions. Concrete canvas consists of a 3-dimensional fibre matrix containing a specially formulated dry cementitious mix. A PVC backing ensures the concrete canvas is completely waterproof. Concrete canvas can be hydrated by spraying or full immersion in fresh or salt water. Once set, the fibres reinforce the cementitious mix, preventing crack propagation and providing a safe plastic failure mode. As a result, concrete canvas provides a thin, durable, water proof and lower carbon alternative to traditional concrete. Concrete canvas is available in 3 thicknesses: (5 mm) CCT1 , (7 mm) CCT2 and (11 mm) CCT3 . For all brochures and documents related to Concrete Canvas, please click here. Application Areas; Bund Lining Channel Lining Slope Protection Petrochemical Industry Concrete Remediation Culvert Weed Suppression Outfalls / Spillways Protection Mining Industry Vent Construction Walls Construction Tank Floor Lining

High density polyethylene with high chemical and physical resistance is used as raw material for these pipes. Today, HDPE Pipes are mostly preferred as a replacement for steel, concrete and PVC pipes. Characteristic Advantages; It is resistant to external impacts. It has high flexibility and is easy to assemble. Internal surface roughness is low. This way, it provides a design advantage in terms of which diameter pipe it will work with. It is resistant to UV rays. Since it does not change the smell and taste of water, it does not cause any harm to health. Its elongation at break performance is high. It is not affected by underground movements and does not have breakage properties. It is resistant to chemicals and impacts, and it has high crack propagation resistance. It is suitable for submarine use. There is no mounting waste. It is not affected by corrosion, so cathodic protection is not needed. Application Areas; Mine tailing storage facilities Mine heap leach facilities Mining solution ponds Sediment ponds Landfills Water supply pipes Sewage pipes Treatment plant pipes Drainage pipes Transfer of various chemicals, also can be used for many other purposes.

No represented companies found.

The company has no registered brand information.

TR

TR