| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

ÜNAL MÜHENDİSLİK VE MAKİNA SAN. LTD. ŞTİ.

Egemenlik Mah. 6106/24 Sokak No: 9 / Bornova / İZMİR / TÜRKİYE

|

Contact Info: +90 232 458 4550

|

Hall: 4

Stand: 406

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Ünal Mühendislik ve Makine Sanayi was established at Izmir as an engineering and manufacturing company by Erdal Ünal in1987. Providing high quality products and keeping its customer satisfaction level at top ; have been its main aim, since its establishment year. Ünal Mühendislik ve Makine Sanayi with its young and dynamic staff is pleased and honored to be in service of its precious customers.

The Jaw Crusher is used for the rapid, safe and efficient crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The outlet opening of jaws infinitely adjustable between 0-40 mm Feed Inlet opening: 200×200 mm Final Fineness : < 2 mm Crushing Capacity: < 600 kg/h Electrical Motor : 7.5 hp, 5.5kW, 1400 rpm, 380 V, 3 p, 50 Hz

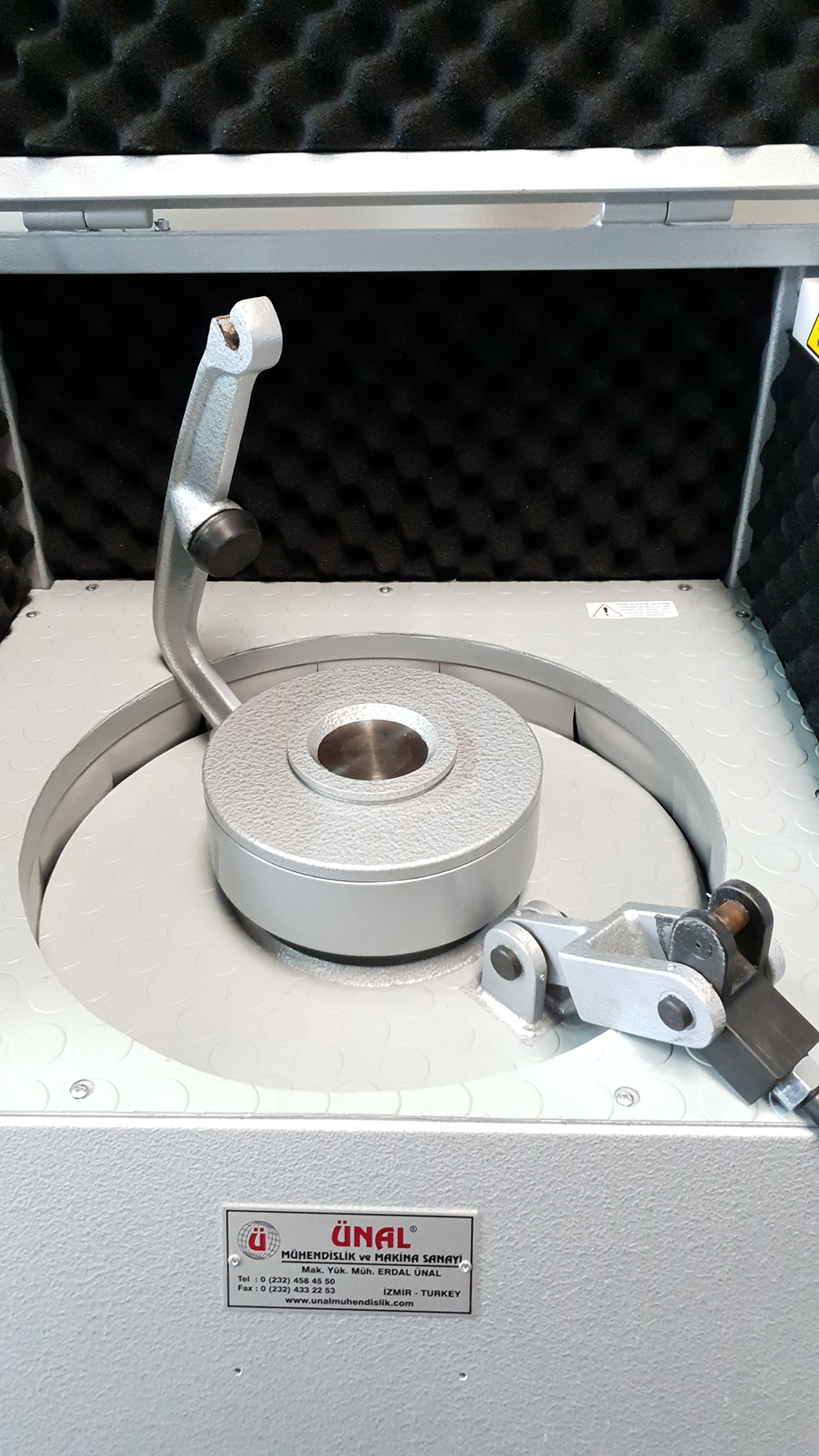

The Vibratory Disc Mill is used for the very rapid, safe and efficient grinding of medium-hard, hard, brittle and tough materials. It is a very useful for sample preparation in laboratories and industrial plants. Application Examples: Alloys, basalt, cement clinker, ceramics, chamotte, coal, coke, construction materials, feldspar, glass and various materials. CE Marked Electrical Motor: 1,5 HP, 1000 rpm, 380 V, 3 p, 50Hz Grinding Set Sizes : 400 cc, 250 cc, 100 cc, 50 cc Feed Quantity: 35-200 ml Feeding Size: < 15 mm Final Fineness: < 38 μm Dijital setting of grinding time from 0 up to 999 h or 999 min. or 999 seconds

The Roller Crusher is used for the rapid, safe and efficient crushing and secondary crushing of medium-hard, hard, brittle and tough materials. It is a very useful for bulk working and pilot plant working. Application Examples: Alloys, basalt, cement clinker, ceramics, chamotte, coal, coke, construction materials, feldspar, glass and various materials. The parallel gap between the rolls infinetely adjustable between 0-20 mm Two Ø250×150 mm hardened steel rolls Feeding Size: < 30 mm Final Fineness : < 500 μm Crushing Capacity: Up to 2500 kg/h Electrical Motor:4 hp, 1400 rpm, 380 V, 3p, 50 Hz, gearbox

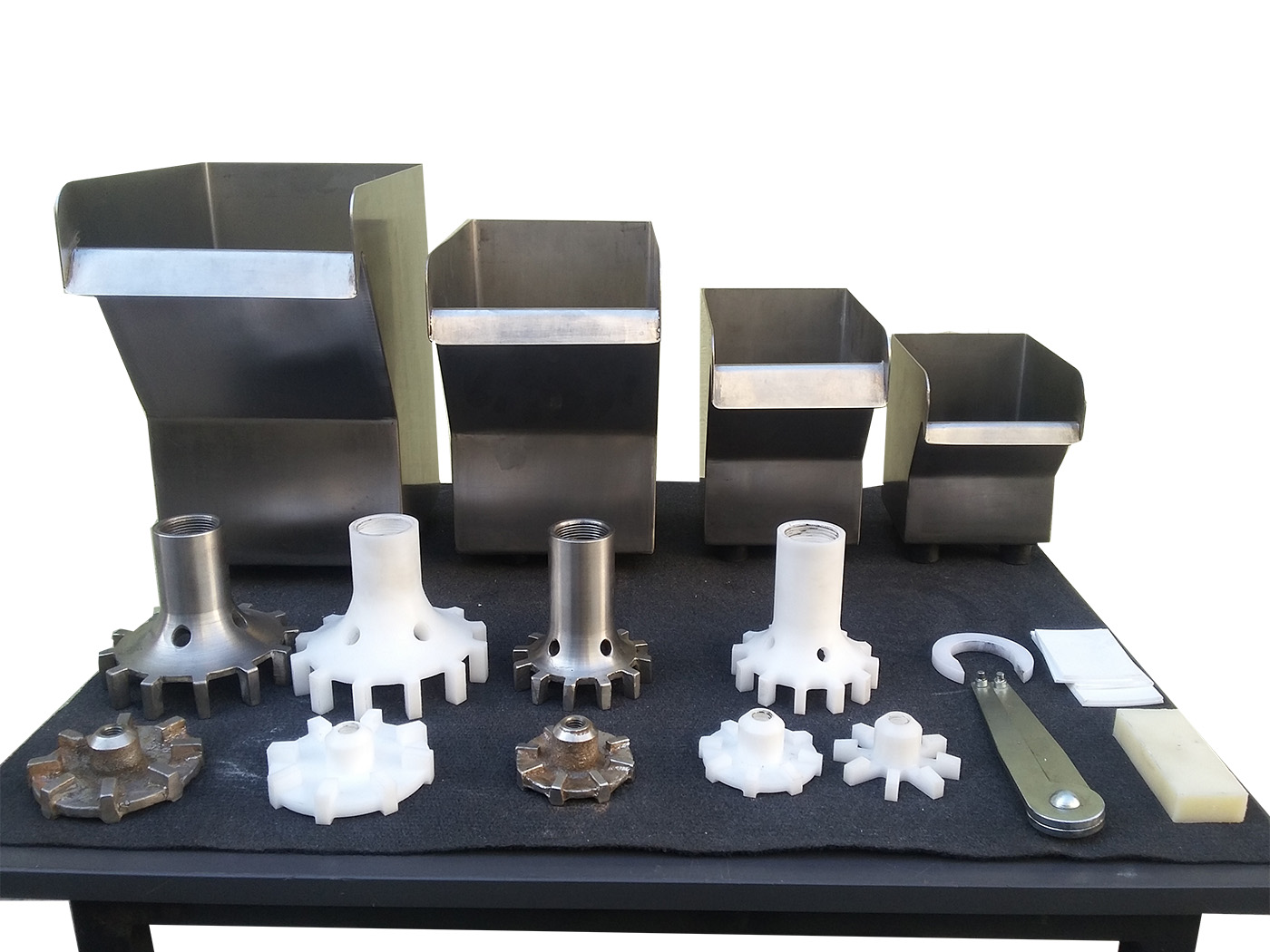

The base of the machine is made of cast iron, the supporting column and arm, drive guard are made of cast aluminium. It is similar to DENVER D-12 Model. Propeller stirrer speed can be infinitely variable between 700 2600 rpm. Provided with a digital electronic speed indicator and protective motor start/stop switch All the contact parts with material are made of AISI 316 stainless steeel. Can handle material from 0.250 kg up to 2 kg at one operation. Four flotation heads in two different sizes provided. Two sets are made of AISI 316 Stainless steel, two sets made of white hard plastic (derlin). The flotation heads can easily be changed. No:1, No:2, No:3, No:4, with 4 cellules made of AISI 316 stainless steel. Electrical Motor: 1 hp, 1400 rpm, 380 V, 3p and variable V-Belt drive. To control and measure the air inflow, provided with two flowmeters as one 1 -5 L/min and one 5 25 L/min, to control pressurized air inflow provide with one air regulator R ¼ with one pressure gauge.

Feeding Size: < 8 mm Feed quantity 500-1500 ml Final Fineness: < 40 μm Rotation speed infinitely variable between 0-100 rpm by an electronic motor speed controller Jar made of AISI 304 stainless steel, Ø178×362 mm 9 L internal volume Easy positioning parallel (grinding) and vertical (loading-unloading) to the ground with a gear reducer with a worm screw and manual handle. Equipped with one charge of milling balls (cromium alloy heat-treated hardened) and one charge of milling rods (AISI 304 stainless steel) Electrical Motor: 1,5 kW, 1400 rpm , 220 V, 3p, 50Hz with gearbox and V belt drive

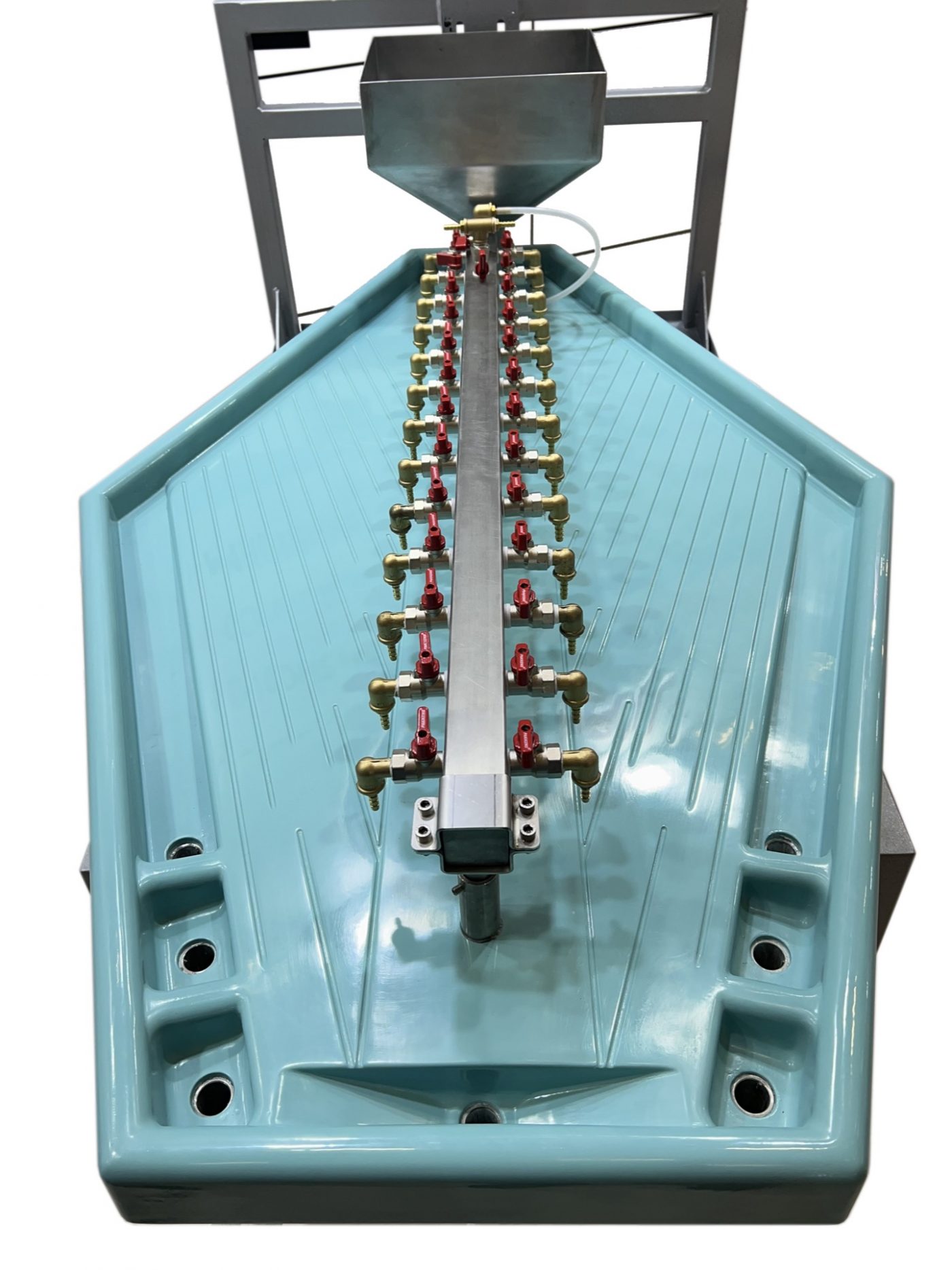

Brand Name ÜNAL- Made in TURKIYE Table Size: Width: 1300 mm Length: 850 mm. Working particle size range between: + 100 µm -1 mm Maximum capacity: 30 kg / hour Water consumption: 0.7 tons / hour Oscillation speed is infinitely adjustable

Rotary Sample Divider equally divides 8 representative samples automatically within accuracy of ± 1 % in weight. Provided with a stainless steel 60 L feeding hopper and an electro-magnetic vibratory feeder Stainless steel dividing head with 8 divisions, carrying 8×6 L sample collecting stainless steel vessels in the form of radial triangular prisms The speed of the rotary dividing head can be infinitely variable between 0-60 rpm by an electronic motor speed controller The system mounted on a mobile 4 wheels frame enclosed in a protective cabinet made of wowen wire sheets, with a front lid with safety switch Feeding Size: <150 mm Net Weight: 300 kg Outside Dimensions: 112x168x141 cm (WxLxH) Driven by a 0,75 kW, 380 V, 3 p, 50 Hz, 900 rpm, electrical motor and gear box

Material Particle Size from 0,038 mm to 20 mm Can accomodate up to three circular sieves (Ø 600 mm) Screen surface per deck approx. 0,25 m2 Integrated with a 50 L feeding hopper and an electro-magnetic vibratory feeder Each deck is equipped with rubber ball cleaning systems in order to keep screen meshes open and clear The screened fractions are collected in four plastic drums connected tightly to the machine Shaking speed is adjustable Electrical Motor: 0.37 kW, 380V, 50 Hz

Working pressure up to 8 kg/cm2 Ø250×400 mm cylindrical pressure chamber made of AISI 304 stainless steel, with an internal volume of 19,6 L Together with air pressure regulator and pressure gauge,bleed valve, cloth and pkg. of filter paper

Feeding Size: < 8 mm Feed quantity 2500-3500 ml Final Fineness: < 40 μm Dijital setting of grinding revolutions from 0 up to 9999 revs. Rotation speed infinitely variable between 0-100 rpm Jar made of AISI 304 stainless steel, Ø305×305 mm 22 L internal volume. Equipped with one main and one spare charge of milling balls(Cr alloyed, heat treated and hardened), one main and one spare sample ball collecting and separating boxes Electrical Motor : 1,5 kW, 1400 rpm, 220 V, 3 p, 50 Hz with gearbox.

No represented companies found.

- ÜNAL

TR

TR