| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

SHIJIAZHUANG WEILIDA PROSPECTING MACHINERY CO., LTD

No.7, Industrial South Road, East Development Zone, Lujiazhuang / Jnzhou / Shiajiazhuang / CHINA

|

Contact Info: +86 139 3184 2198

|

Hall: 6

Stand: 618-03

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

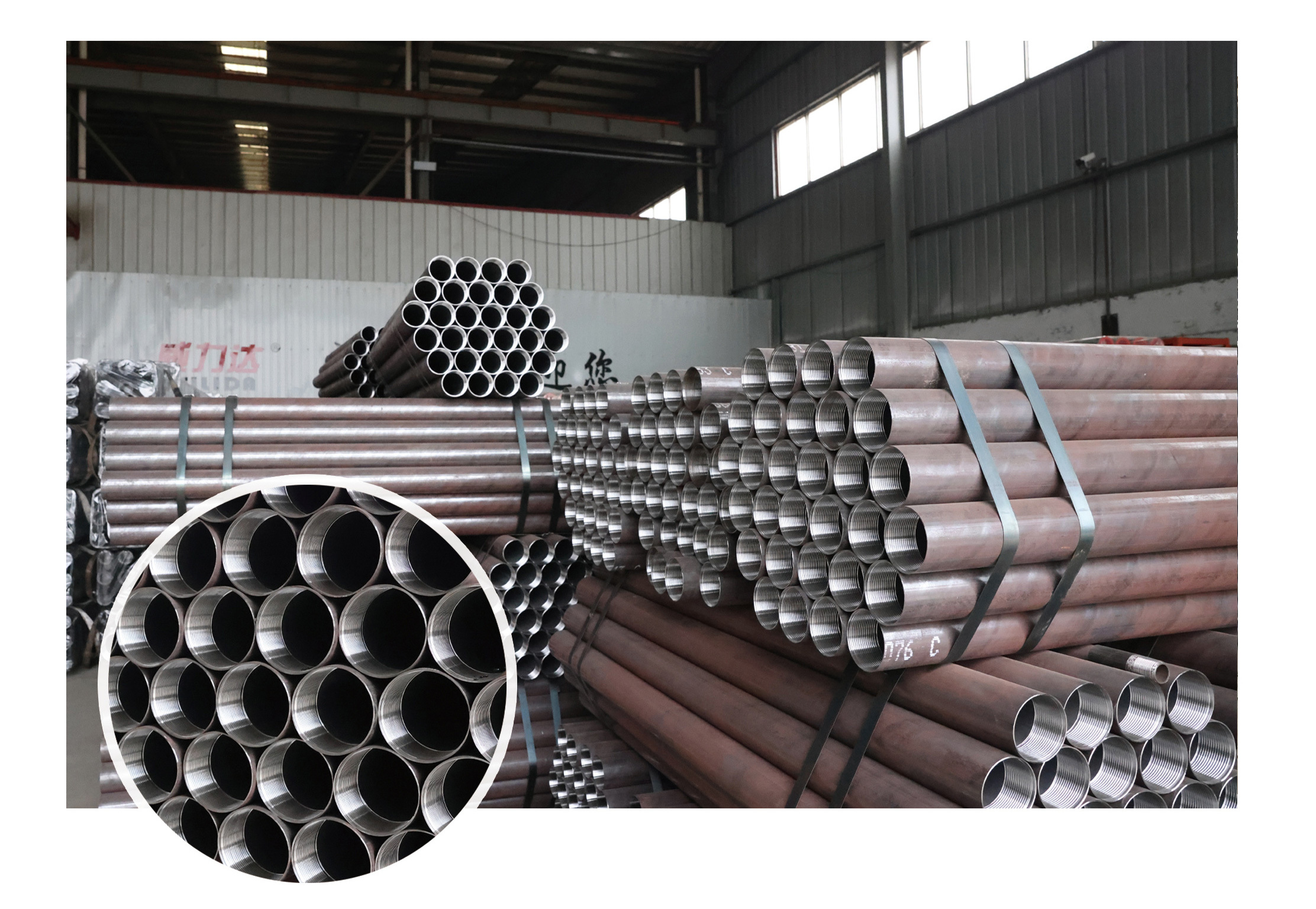

Shijiazhuang Weilida Prospecting Machinery Co., Ltd. (formerly known as North Petroleum Geophysical Exploration Machinery Factory) was founded in 1988. It is located in Jinzhou City, Shijiazhuang City, an important industrial base in Hebei Province. It has a beautiful environment and a superior geographical location. It is 5 kilometers away from the Jinzhou South Exit of Shiheng Expressway, 15 kilometers away from Xinji South High-speed Railway Station, and 50 kilometers away from Zhengding International Airport. Our company has a modern factory area of 13,000 square meters and 80 employees. It is one of the few domestic and international enterprises integrating drilling tool design, manufacturing, testing, domestic and foreign trade sales. We can produce GB, Gost, API and European standards drilling tools, and can also design and manufacture special specifications of drilling tools according to customers needs. Our company has a number of domestic advanced CNC lathes, friction welding machines, pipe end upsetting and thickening machines, and complete production equipment. The quality management system has been established in accordance with ISO9001, and the professional system management personnel have conducted multiple trainings for all employees. The quality management system is in perfect and effective operation. From the signing of the order to the inspection and delivery of finished products, we use various identification methods such as labels, lettering, and spray paint, and record all data to ensure product traceability. We are also equipped with various specifications of thread gauges, pitch testing instruments, taper testing equipment, flaw testing equipment, hardness testing equipment, with the required physical and chemical testing equipment, and we can conduct comprehensive mechanical performance tests on drilling tools as required. We always take sincere cooperation, reliable quality and high-quality service as our corporate philosophy, improve self-management level, adjust market layout, improve product technology content, and solve customer needs, so that customers can buy with confidence and use comfortably.

DTH drill pipe is mainly used for rock crushing, anchoring drilling, geothermal air conditioning hole, water well drilling, etc. Materialsare purchased from well-know large enterprise of domestic. The ends of pipe are lU processed,then temered after friction welding.Drill pipe joints are quenched and tempered after rough machining,and surface nitriding treatment after finishing,that makes the joints more wear-resistant and easy to disassemble without thread gluing, breaking and joint expansion and cracking. Precision imported CNC lathes and customized forming cutters are used for thread processing. All threads are equipped with thread gauges that meet international standards. All process can extend service life of drill pipe andmake the quality stable and reliable. We can produce DTH drill pipes of different materials, lengths, diameters, and wall thicknesses, and we can also customize drill pipes according to the materials, lengths, wall thicknesses, and threads required by customers.

Friction Welding Water Well Drill Pipe is mainly used in deep drilling of geothermal energy, water well drilling, etc.The pipe body is made of materials produced by well-known steel companies in China. Both ends of the pipe body adopt EU and IU processes, and are tempered after friction welding.The drill pipe joint is subjected to quenching and tempering heat treatment after rough machining, and surface phosphating and nitriding treatment after fine machining of threads, which effectively eliminates the probability of failure such as sticking, breakage, and outer diameter expansion and cracking. It is more wear-resistant and easy to disassemble. Precision CNC lathes and customized forming cutters are used for thread processing and All threads are equipped with thread gauges that comply with international standards.We can not only produce friction welding water well drill pipe of different materials, lengths, diameters, and wall thicknesses, but we also accept customization according to the requirements of customers.

We can produce virous of oil drill pipes , mainly including API 5DP drill pipe and SY oil standard drill pipe. We can match the same grade of drill pipe joints according to customer s requirements and meets API SPEC 7-1 standard. The advanced friction buffing welding equipments can adjust the welding parameters to the best position to ensure the quality of the welding strip; the heat treatment process of internal and external simultaneous cooling, that make the mechanical properties more uniform and stable. Our company has equipped with automatic measuring and weighing , and automatic spray marking machine, that ensure products are traceable. Advanced drill pipe thickening and heat treatment production line are also equiped, It adopts CNC full-length heating furnace, quenching machine and tempering furnace. Advanced heat treatment processes and precise temperature control ensure the mechanical properties of the pipe. The hydraulic pressure of the pipe body ensures the straightness of the pipe body and the coaxiality of the pipe body.We can not only produce of oil drill pipes of different materials, lengths, diameters, and wall thicknesses, but we can also customize oil drill pipes according to the requirements of customers

Adapter sub/X-over sub/ reducer joint is used in rock drilling, anchor drilling, oil drilling, and geological water well drilling operations. It is used for the conversion connection of drill string components. It is one of the main tools for connecting the upper drilling tool and the lower drilling tool. Our company can provide various forms of conversion joints.The conversion joint is made of 35CrMo, 42CrMo, and 4137H materials.Quenching and tempering heat treatment after rough machining, and surface phosphating and nitriding treatment after fine machining of threads, which can effectively eliminate the probability of failure such as sticking, breaking, and outer diameter expansion cracks, making it more wear-resistant and easy to disassemble.

We can manufacture both Pin-Box casing and Box-Box casing with Pin-Pin nipple connection. We also supply various sizes of inner rod, saver subs and casing bits, all products comply with API specifications, and can be customized according to the material, length, wall thickness and thread required by the customer.

This kind of pipe is used for geological prospecting, water well drilling, eothermal well drilling project, etc. The finer thread drill pipe is a drilling tool that is connected to the lock joint to transmit the torque of the drill to the bottom hole and to transport the drilling fluid. The rod material is selected from Shanghai Baosteel STM-R780 (42MnMo7), which is not easy to be bent or broken, and the performance is stable and reliable. The rod end is heated by medium frequency, hydraulically thickened and thickened, and 12 hours of buried tempering ensures the compactness of the drill pipe and improves the mechanical performance. All of them are made of precision imported CNC lathes, and the custom-made knives are threaded, which ensures the tightness of the connection with the tool joint.

The Lock Tool Joint is made of 35CrMo or 42CrMo material.Quenching and tempering heat treatment after rough machining, surface phosphating and nitriding treatment after finishing threads,which can effectively eliminate the probability of failure such as sticking, breaking, and outer diameter expansion cracks, making it more wear-resistant and easy to disassemble.Precision CNC lathes and customized forming cutters are used for thread processing, which can not only ensure the tight spacing of the drill pipe and joint threads, but also ensure the precision and interchangeability of the drill pipe and lock tool joint.

HDD drill pipe is mainly used in horizontal directional drilling pipeline crossing and laying projects. The pipe body is made of special materials that comply with API standards and has stable performance. The thickened pipe end complies with API5DP standards. The thickened pipe body is quenched and tempered and heat treated. The steel grade can be Up to G105 or S135. The tool joint is made of forged blanks. After rough machining, it is tempered and heat treated. After finishing, the surface is nitrided. The threads of the double shouldered high-torsion joint adopted a kind of internal and external composite shoulder structure design, and are all processed by precision CNC lathes. The tight pitch of the threads is strictly guaranteed. Compared with threads of the same specification, it has higher tensile strength and torsional yield strength. All threads are equipped with thread gauges that comply with international standards, so the performance of our drill pipes is stable and reliable. We can produce HDD friction welding drill pipes of different materials, lengths, diameters, and wall thicknesses, and we can also customize drill pipes according to the materials, lengths, wall thicknesses, and threads required by customers.

Rotary percussion drill pipe is mainly used for rock crushing, anchoring drilling, geothermal air conditioning hole, water well drilling, etc. Materials are purchased from well-know large enterprise of domestic. The ends of pipe are IU processed, then temered after friction welding. Drill pipe joints are quenched and tempered after rough machining, and surface nitriding treatment after finishing, that makes the joints more wear-resistant and easy to disassemble without thread sticky, breaking and cracking. Precision imported CNC lathes and customized forming cutters are used for thread processing. All threads are equipped with thread gauges that meet international standards. All process extended service life of drill pipe, the quality is stable and reliable. We can produce rotary percussion drill pipes of different materials, lengths, diameters, and wall thicknesses, and we can also customize drill pipes according to the materials, lengths, wall thicknesses, and threads required by customers.

No product info found.

No represented companies found.

The company has no registered brand information.

TR

TR