| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

POLİMAK GRUP ENDÜSTRİYEL ÜRETİM SAN. A.Ş.

Malıköy Başkent OSB 52. Cadde No: 3, 06909 Sincan / / ANKARA / TÜRKİYE

|

Contact Info: +90 312 354 0976

Web: https://polimak.com/

|

Hall: 8

Stand: 827D

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Polimak is a leading engineering and fabrication company, specializing in bulk solids handling technologies for over four decades. Our wide range of versatile bulk material handling machinery is appropriate for value-added logistics as well as handling powders, granules and pellets in the mining, minerals, and agriculture processing industries. Polimak systems range from demanding production lines to heavy industrial applications. Our team of experienced and motivated specialists is dedicated to providing the bulk solids-processing industry with solutions that are not only efficient, reliable and cost-effective but truly extraordinary.

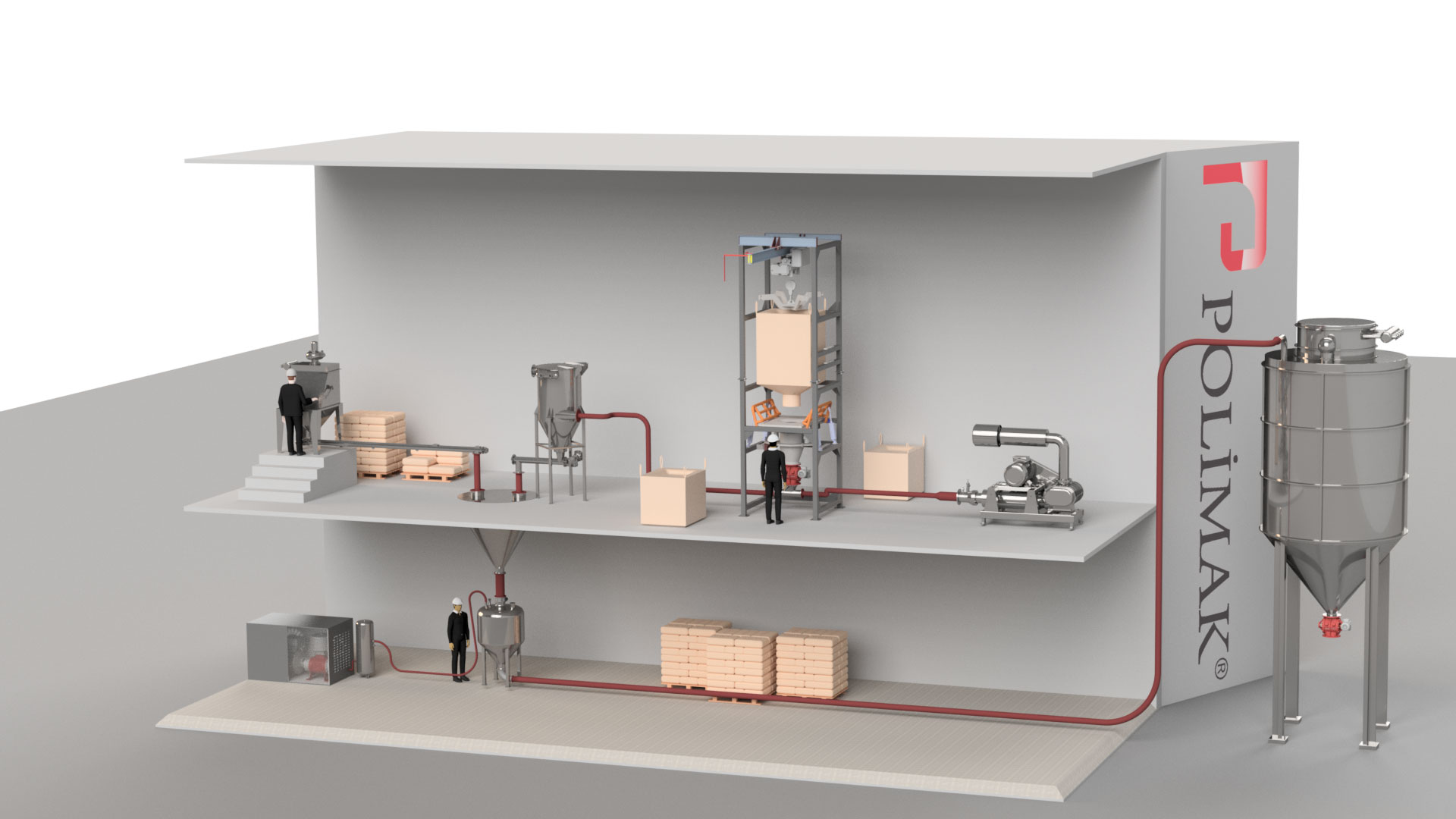

Material transfer systems enable the transportation of bulk materials from production sites to storage areas or from one point to another during the production process, especially in mines and industrial facilities. Dilute phase and dense phase pneumatic conveying systems provide solution to several mining industrial application including coal mining and rock dust (typically pulverized limestone).

A rotary valve or an airlock feeder is a bulk material handling equipment used to modulate the flow of dry bulk solids from upstream equipment such as storage silos, hoppers and dust collection systems to downstream systems like pneumatic conveying systems, belt conveyors, and screw feeders. Polimak is an industrial company concerned with the design and production of various machinery used for handling dry bulk materials. With over four decades of experience in the bulk solids industry, our objective is to devise and produce cutting-edge bulk solids machinery that provide quality performance during bulk material handling for our clients. Rotary valves are referred to by various names, with the term airlock valves being the commonly used one. Its primary function is to regulate bulk material flow from one piece of equipment to another and maintain a constant air pressure between the two ports of the valve (inlet and outlet). This is attained with the help of the rotor blades. Airlock valves are a fundamental component in bulk handling systems. They are widely used in many different industries such as food, chemical, plastics, cement, agriculture and many others for various bulk material handling processes.

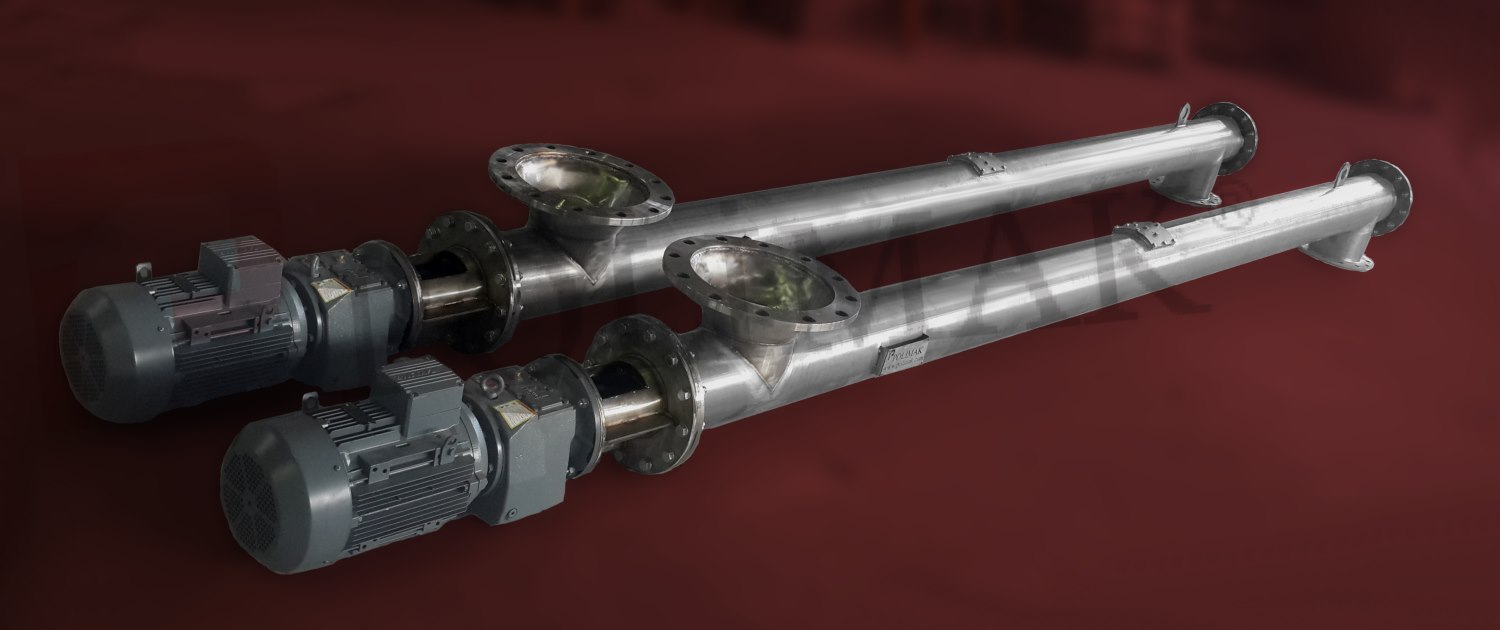

Bulk material handling processes including plastics production, power plants, construction, food processing and mining depend heavily on industrial bulk material transportation equipment such as screw feeders and screw conveyors also known as helical conveyors. They are used in conveying powdered and granular materials mechanically. There exist wide range of screw conveyor types and configurations. The physical properties of bulk solids and type of application effects the design of screw feeder. Conveying capacity, horizontal and vertical distances, type of bulk solid should be considered to select a proper screw conveyor model. Screw diameter, screw pitch, inlet and outlet dimensions, motor power and casing type are major properties of screw conveyors., Polimak designs and manufactures the screw conveyors to meet specific design parameters and applications.

Dust collection systems and jet pulse filters are used to prevent dust emissions during handling of bulk solids in powder or granule form in industrial processes which are harmful for health and environment.

No product info found.

Bulk solids in the shape of powders and pellets are stored and moved around in many industrial applications. They are stored in bags, bulk bins, and godowns and have to be moved around by using trucks or other bulk carriers. Loading and discharging these solids is a major logistic issue and has to be managed. Our systems give you a strong capability to move around such materials efficiently, safely, and economically due to their excellent design and robust construction. Check out these systems and select the one best suited to your application. Look at our Mobile Bulk Truck loading processes. Our unique technology guaranties quick emptying of bags and robust, automatic and dust-free loading in the truck . That is why our Mobile Truck loading systems are being used all over the world with very high client satisfaction. They are not only efficient, easy to maintain and above all economical. If your applications require Big bag discharging and loading look at our models and we are sure that you will find one that exactly suits your needs. Our System consists of a mobile platform, big bag discharger, loading screw, telescopic loading chute and dust collector. System can be towed by a forklift and screw conveyor can be brought to horizontal position for easier and safe transport. There are many options to choose from. Select the model that meets your requirements completely.

Dry bulk solids are transferred and delivered with different ways. FIBC (Flexible Intermediate Bulk Container) also know as big bags are one of the the most preferred way of handling bulk materials in granular and powder form. Well designed big bag handling systems are needed to be able to fully benefit from big bags. Big bag discharging stations are designed for unloading of bulk bags in effective and safe way. Different types of bulk materials can be handled, starting from free flowing granules to poorly flowing sticky fine powders. Modular design of big bag discharging systems make them easy to be configured for each application need. While standard models have simple frame and discharge hoppers, high level models have complete solution in single main frame. Big bag discharging, product storage, dust collection, dosing and conveying can all be done in single unit.

No product info found.

No represented companies found.

The company has no registered brand information.

TR

TR