| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

NUCLEAR INDUSTRY YANTAI TONICN GROUP CO.,LTD

C Zone (Songshan), Economic Development Zone, Qixia City, Shandong Province / / Yantai / CHINA

|

Contact Info: +90 05 ext. 353379738

|

Hall: 6

Stand: 616-07

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Nuclear Industry Yantai Toncin Group Co., Ltd. Located in Shandong province, China, which integrated enterprises of filter industry, wrapping machine, advanced manufacturing industry and new materials industry, formed the industrial pattern of common development of filtration separation machinery, wrapping machine, new material industry and high-end equipment industry. Toncin worked with the domestic well-known colleges and research institutes to establish a long-term technical cooperation and engaged in filter industry and wrapping industry 24 years by an experienced team of production, research, development, sales and service, has a perfect product processing, quality assurance and after-sales service system, walking at the forefront of filter industry and wrapping industry. Nuclear Industry Yantai Toncin Group Co., Ltd. Currently own 5 state-level high-tech enterprises, maintain 177 valid patents, including 38 invention patents, presided and participated in the formulation of more than 10 national standards and industry standards of the Horizontal Vacuum Belt Filter, Vertical Automatic Filter Press, Ceramic Disc Vacuum Filter, SSPF Smart Press Filter, thickener, Wrapping Machine and so on.

The DU rubber belt vacuum filter is equipment that realizes solid-liquid separation with vacuum negative pressure as driving force. In the structure, its filtration section is arranged along the horizontal length and it can continuously perform filtrating, washing, blotting, and filter cloth regeneration etc. The equipment has the advantages of high filtration efficiency, large production capacity, good washing effect, low water content of the filter cake, flexible operation and low maintenance cost etc. It can be widely used for solid-liquid separation in the fields of metallurgy, mining, chemical, papermaking, food, pharmacy and environmental protection etc. and it particularly has a good application in the flue gas desulfurization gypsum dehydration (FGD).

TC series ceramic vacuum filter is a new type high-effect, energy saving filtration equipment, using vacuum and ceramic plate with micro-holes for solid-liquid separation. The plate material is corundum, resisting to almost all temperatures, and has a long operation life. The micro-holes in plates only allows liquid to flow through but not air and solid. Filtrate is drawn through the ceramic plates as they are immersed into the slurry cabin, and cakes forms on the surface of the Plates.

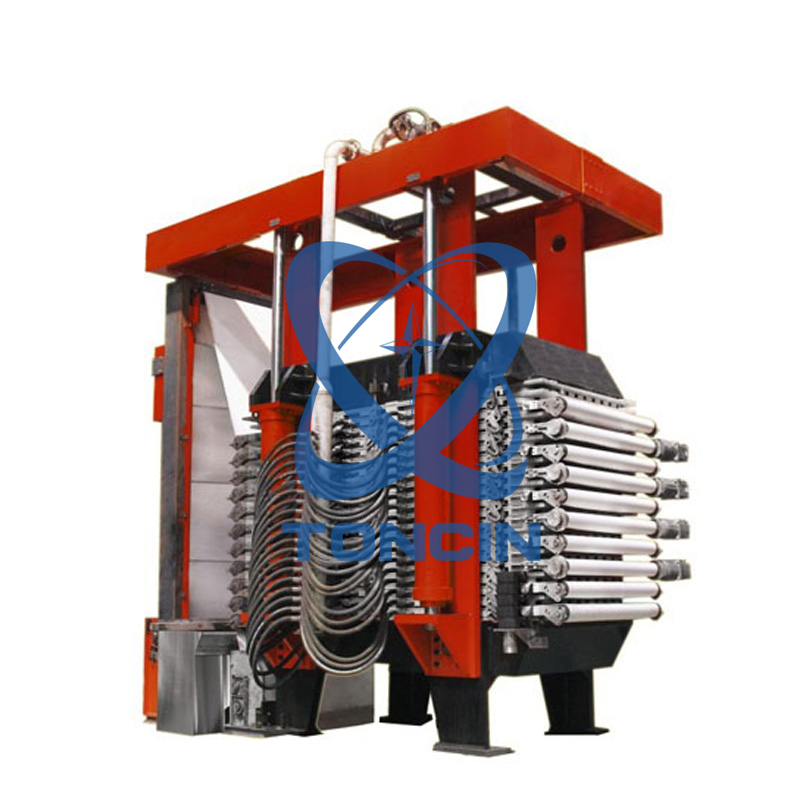

HVPF vertical automatic press filter is the most advanced filter that the world has ever get. Vacuum has a limit, but Pressure not. HVPF vertical automatic press filter use air or water to form a huge pressure difference on both sides of filter cloth to achieve very efficient separation of solid and liquid. As filter plate is closed, slurry is pumped into filter chamber through slurry pipes. Part of filtrate then enter the filtrate chamber through filter cloth because of gravity. Then high pressure water force rubber diaphragm to extrude filtrate from filter cake. When these process is finished, the driver run filter clothes and filter cakes is discharged from both sides of filter cloth.HVPF vertical automatic press filter can be applied in mining, metallurgy, chemical industry, pharmacy and food industries. It is a kind of high capacity, energy-saving, automatic solid-liquid separation machine.

The thickener has multiple national patents such as center drive, high-efficiency feeding hopper and automatic rake lifting technology. The adoption of the heavy-duty core design ensures the machine normal running in extreme conditions, greatly boosting the concentrating efficiency. GNZ type of high-efficient thickener achieves the efficient dewatering by the action of material itself gravity and flocculating settlement. The slurry is mixed with the flocculating agent in the feed tank and fed to the high-efficiency feed hopper (steady flow tank). After the degassing and energy dissipation by the steady flow tank, the material is fed along the horizontal tangent of the inner tank of the steady flow tank, which is equipped with multiple flocculent adding points based on the material nature; the material and the flocculating agent are settled downwards after mixed for the second times; then they are transported along the parabola direction by the distributor disc at the bottom of the tank; the settled material is scraped by the rake to the center throat of the pool body for centralized discharge.

The SSPF smart filter press is a fast opening and closing plate filter press which mainly consists of the electrical control system, hydraulic control system and the main engine. When the equipment is in operation, the mechanical transmission mechanism drives the hydraulic cylinder and drags it to reach the designated position. After the hydraulic cylinder is locked by the locking device, the hydraulic cylinder protrudes and the filter plates of the filter press are pressed tightly to form a filter chamber between the adjacent filter plates, with peripheries sealed. The materials enter each filter chamber from the feeding hole through the feeding pump at a certain pressure. The solid-liquid separation is achieved by the pressure difference formed between the two sides of the filter medium by the feeding pressure of the feeding pump. After that, the materials are trapped in the filter chamber and the filtrate is discharged from the water hole of the filter plate through the filter cloth. After a period of time when the filtrate no longer flows out, the filtration and dehydration process is completed. You shall stop feeding and determine whether to perform high pressure diaphragm squeezing, washing and drying in light of the process requirements. Then the hydraulic cylinder is retracted, the locking device in unlocked, the mechanical transmission mechanism drives the hydraulic cylinder, pulls out the filter plates and removes the filter cake and the equipment will enter the next filtration cycle after the filter cloth is cleaned.

The water ring vacuum pump and compressor are energy-efficient products developed by our company based on years of scientific and research achievements and production experience as well as combined with international advanced technology of similar products. It is commonly used for suctioning solids-free, water-insoluble and non-corrosive gases so as to create vacuum and pressure in a closed container. By changing the structural material, it can also be used to pump corrosive gases or apply corrosive liquids as working fluids. And it is widely used in papermaking, chemical, petrochemical, light industry, pharmaceutical, food, metallurgy, building materials, electrical appliance, coal washing, mineral processing, fertilizer and other industries.

No represented companies found.

The company has no registered brand information.

TR

TR