| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

İDEAL MAKİNA END. ÜRÜN. SAN. VE TİC. A.Ş.

Esenkent Mah. Natoyolu Cad.No: 277 34776 Ümraniye / / İSTANBUL / TÜRKİYE

|

Contact Info: +90 216 540 8855

|

Hall: 7

Stand: 710

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Ideal Makina A.Ş. was established in Istanbul in 2004; It has become one of the leading companies in the sector with its expertise, knowledge and after-sales service and maintenance services in the field of all industrial pumps, nitrogen - oxygen generators and compressors and complementary equipment and systems used in fluid liquid transfer, gas generators and compressed air applications. Its expert staff consisting of 45 experienced engineers and technicians in its head office and workshop, and a technical service team of 28 people provide training and service planning support to end users in order to ensure the continuous and trouble-free operation of the installed equipment, as well as malfunction, maintenance and repair services. Ideal Makina A.Ş., which has undertaken projects not only in Turkey but also abroad since 2010, has exported to 60+ different countries and delivered the systems it supplied to its customers in working condition by performing on-site assembly and initial operation. Ideal Makina A.Ş. produces tailor-made solutions to the demands of its customers in its workshop with a 5000 m2 closed area in Istanbul. Nitrogen & Oxygen Generators and Tube Filling Containers, Plug & Play Mobile Gas Generators on Chassis, Air Gas Compressor Stations, Chemical Dosing Sets, Polymer Opening Units, Pneumatic Transport Systems, etc. User-friendly products are manufactured in accordance with technical specifications. Ideal Makina produces with its own design as a result of R&D studies; It has made barrel unloading system, dosing skids, CATOX nitrogen purification unit and UHP high purity (99.5%) oxygen generators available to its customers. With its R&D team that constantly improves itself and seeks better, Ideal Makina continues to develop products that offer optimum solutions and offer them to the service of users.

Seepex mono pumps are used in numerous businesses in a wide variety of sectors, providing smooth fluid transfer under the most difficult application conditions. Seepex mono pump has a wide capacity range up to 500m3/h flow rate and 96 bar pressure. Mono pump is suitable for the transfer of low and high viscosity fluids, as well as abrasive, sticky, crushing and foaming sensitive fluids. Mono pump (mud pump) provides a smooth and linear, measurable flow and operates silently and vibration-free. Based on these features, mono pumps can also be referred to in different ways within the industry, such as mud pump, waste water pump, screw pump, linear pump, screw pump.

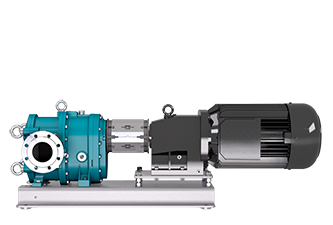

Börger is a world-renowned brand for lobe pumps. Solid transfer pumps are powerful, convenient and effective. Börger pumps can be used in dirty, muddy and corrosive environments without any problems. Börger pumps are self-priming, positive displacement pumps that can operate without valves. The rotor pair rotating synchronously creates vacuum in the suction section. This vacuum draws liquid into the pump inlet. The fluid is transferred to the pressurized environment according to the rotation direction of the rotors. If the rotation direction of the rotors changes, reverse flow is achieved.

Centrifugal pumps made of thermoplastic material are pumps with electric motors and varying capacities that are used efficiently in applications that require rapid transfer of liquids. By selecting the parts of the pump in different materials, the most suitable pump in terms of chemical resistance to the fluid and the environment can be determined.

JESSBERGER barrel pumps pump acidic, basic, corrosive, aggressive, alkaline, flammable and combustible fluids such as liquid soap, honey, chocolate, molasses, cream, jelly, paste, glue, jam, etc. from barrels, containers, drums, IBC tanks and other containers. shampoo, dye etc. It is produced in accordance with CE standards for safe, clean and problem-free transfer of viscose products. Jessberger barrel pump is a set with PP, PVDF, AISI, ALUMINUM material pump pipes selected specifically for the fluid to be transferred, and motors specifically selected for the process. In the case of the Jessberger barrel pump, it is possible to use the same engine with different material pump pipes.

Hose pumps, also known as peristaltic pumps, are suitable for the transfer of corrosive and abrasive chemicals, as well as liquids containing solid particles and high viscosity fluids. Materials that come into contact with liquid are hose and hose fittings. The appropriate pump is determined with the selected hose according to the fluid. The pumps can run dry and the direction of rotation can be changed. When the hose reaches its previous form after compression, it creates an almost full vacuum feature that draws all the vacuum in the hose. Thus, very viscous liquids can be transferred without any problems using Boyser hose pumps. The pump body is half filled with specially manufactured oil to extend the service life of the hose, cool and lubricate the pump. Since the fluid only comes into contact with the hose and not the rotating parts, the hose pump is well-suited for abrasive and corrosive applications.

DEAL MAKİNA PSA Oxygen Generator Systems produce gaseous oxygen from compressed air in the field where they operate and offer a cost-effective, continuous and safe alternative to traditional oxygen gas sources such as cylinders or cryogenic liquid. Our Oxygen Generators; It is available in 21 standard models with capacities ranging from 0.5 to 2000 Nm3/hour with 95% purity. The design is made for 24/7 operation. Each oxygen generator is equipped with automatic start and stop function, which allows it to automatically start and stop according to the user s oxygen consumption.

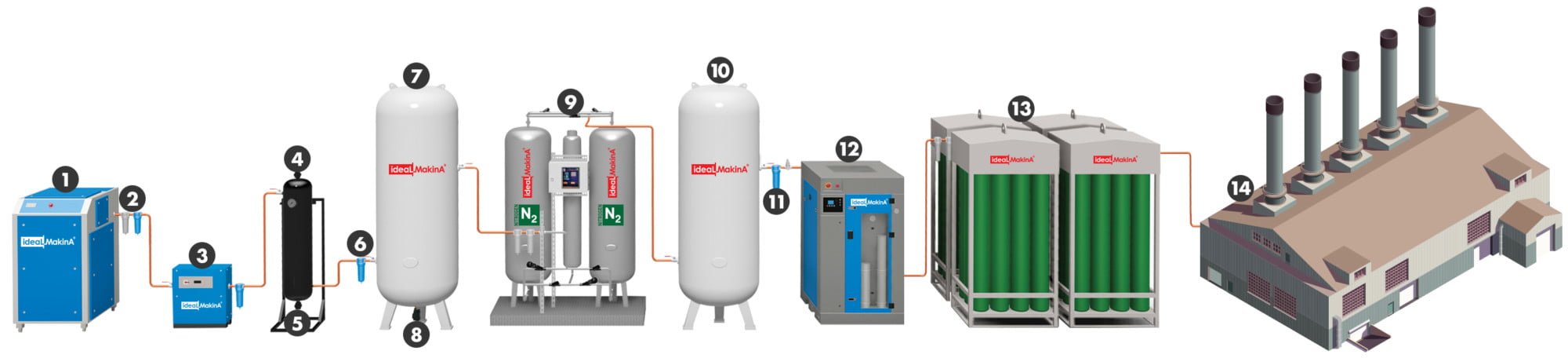

IDEAL MAKİNA produces nitrogen generators with 30 models and a capacity range of 0.5 - 5,000 Nm3/h, with purity up to 95% - 99.9999% (1 ppm). IDEAL MAKİNA is a leader in the sector with more than 500 systems it has installed in the domestic and international markets since 2005. IDEAL MAKİNA PSA Nitrogen Generator Systems produce gaseous nitrogen from compressed air in the field where they operate and offer a cost-effective, continuous and safe alternative to traditional nitrogen gas sources such as cylinders or cryogenic liquid. The design is made for 24/7 operation. Each nitrogen generator is equipped with auto start and stop function, which allows the user to automatically start and stop according to nitrogen consumption

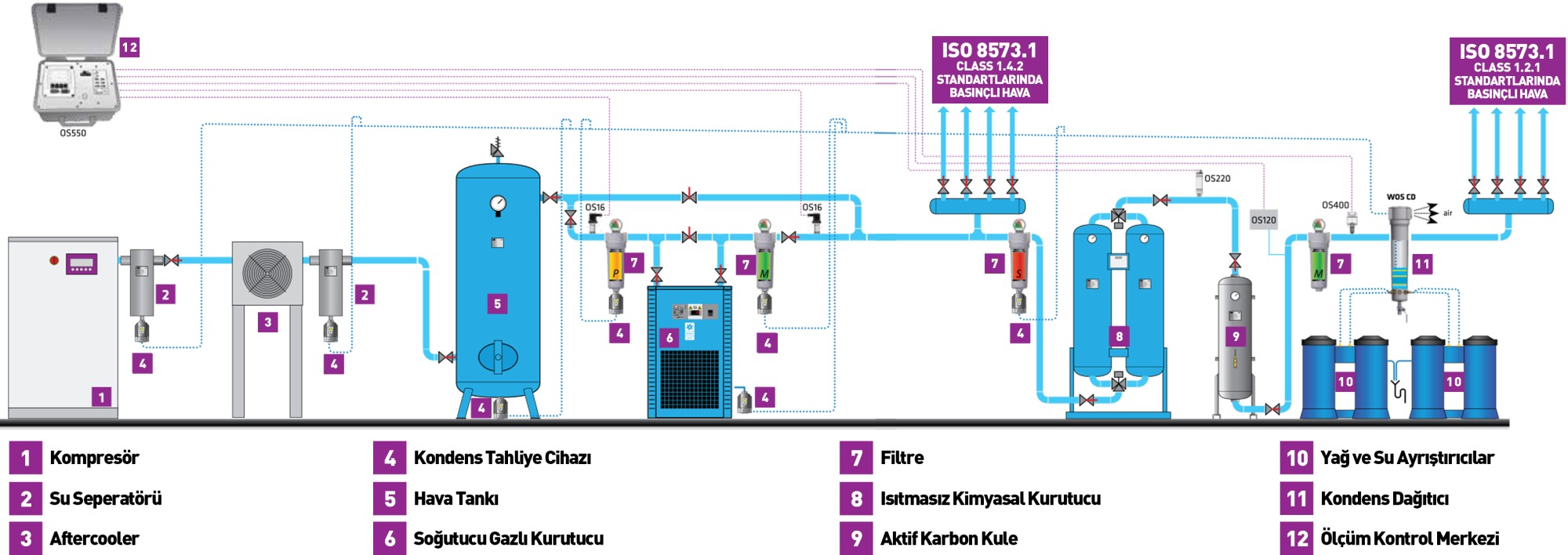

We offer high efficiency solutions with the gas-cooled dryers of the Italian manufacturer FRIULAIR brand, of which we are the distributor in Turkey. Producing correct quality air is an issue of utmost importance for users. Compressed air may contain various undesirable contaminants such as water vapor, oil, particles, dust, etc. If polluted air comes into contact with the equipment in the production process and the final product, it may cause equipment malfunctions and increase product costs, thus increasing operational costs significantly. In line with your and your company s quality policy, it is very important to determine the desired air quality and to establish the system by deciding on the requirements of the compressed air system according to this need. The quality of compressed air should be determined by various dryers and filters and the air quality needs of the consumer.

Ideal Makina s product range includes screw, piston and scroll air and gas compressors, mainly oil-free and oil-injected. Our screw compressors use quality components with 7,10, 13 and 15 bar pressure options in the range of 2.2 kW-315 kW; It is produced on the basis of long life and efficiency. Our Oil-free Compressors; It consists of German-manufactured RENNER and BOGE brand products in scroll, screw and piston types. Oil-free scroll type compressors; It has a capacity range of 1.5 30 kW. Oil-free piston compressors are; It has a capacity range of 0.75 11 kW. Oil-free screw compressors are; It offers a wider usage range with a capacity range of 18.5 355 kW. They mostly meet the need for oil-free compressed air in sectors such as medical, pharmaceutical, food, chemical and electrical - electronics. Our Booster Compressors; It is used to absorb existing conditioned 5-10 bar compressed air and gas and raise it to higher pressures (20-40 bar). German BOGE brand booster compressors, with 115 years of experience, are the most preferred compressors in the world in pet inflation and gas pressurization processes. Our High Pressure Compressors; They are used to fill Nitrogen, Oxygen, Hydrogen and dry air into the tubes at a pressure range of 150-350 bar.

Pneumatic conveying systems; It is used to transfer substances, usually in granular/powder form, from one place to another by means of air flow moving within a transmission line. The common operating principle of pneumatic conveying systems is to transmit the kinetic energy of the air flow to the load. Since air is a clean energy source and the system operates completely closed, material losses and environmental pollution are reduced to a minimum, and in most cases, transportation is carried out with zero loss.

- SEEPEX

- İDEAL MAKİNA

- BÖRGER

- BOYSER

- JESSBERGER

- DEBEM

- PEDROGIL

TR

TR