| Company Name | Contact Info | Location | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

BELLİ MADEN MAKİNALARI SANAYİ VE TİCARET ANONİM ŞİRKETİ

Saray Mah. Saraykent San. Bölg. 73. Cadde No: 6 / Kahramankazan / ANKARA / TÜRKİYE

|

Contact Info: +90 543 884 3174

|

Hall: 6

Stand: 633A

|

||||||||||||

| Product Groups | ||||||||||||||

|

||||||||||||||

- Company Info

- Products

- Represented Companies

- Company Brands

Belli Makina aims to achieve sustainable success for its collaborators operating in the mining industry, as a result of the engineering studies supported by product innovation and application experience.

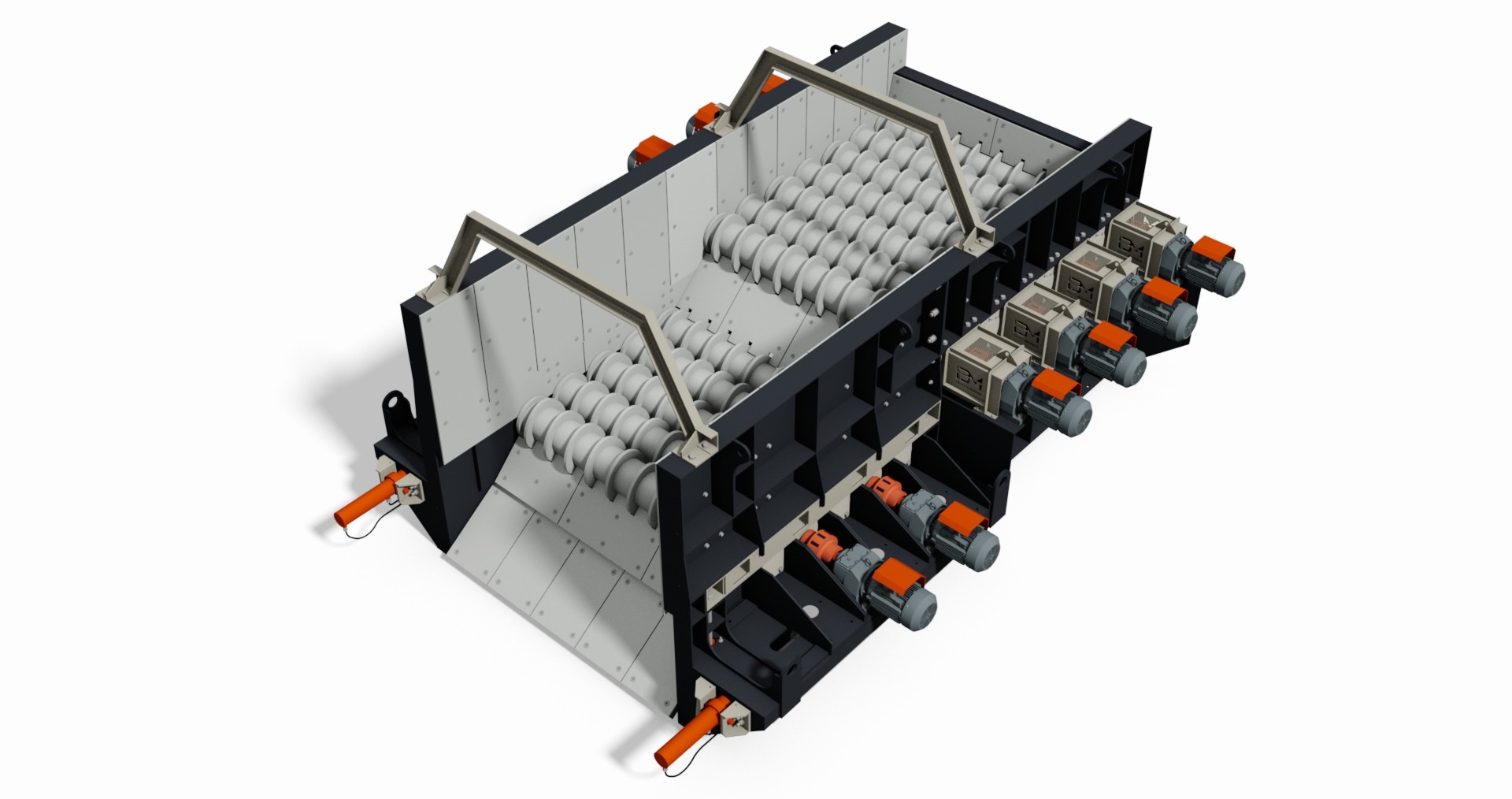

With the developing technology in recent years, wobbler feeders have proven to be an effective mechanism in feeding and screening moist and sticky materials in stone and mines. Wobbler feeder consists of elliptical disks mounted in a gradual configuration on rollers that carry, loosen and rotate the material by giving it a certain acceleration movement. While the separated fine materials fall down one by one through the gaps between the drums, the coarse materials are carried forward without being subjected to any compression, thanks to the gripping ability provided by the elliptical structure of the discs. They are significantly superior machines to oscillating screening mechanisms for feeding and screening all types of bulk materials, including loamy or clayey soil. Additionally, because the material is transported horizontally, it is fed smoothly and consistently. This reduces the density in the crushers, resulting in less wear and less energy consumption. The modular body and drum design is suitable for a variety of underground and aboveground applications with possible arrangement options. BELLİ MAKİNA® Wobbler feeders offer services with a fixed sieving opening or optionally adjustable sieving opening with their WBH and WBS series compact designs to meet all customer requirements. The modular body structure offers the opportunity to create a body in almost any desired size by combining them individually or in stages. The modular body structure and sieving aperture adjustment offers the opportunity to work in various configurations and in more than one position. Suitable for a wide range of operations on limestone, clay, coal, salt, natural stone, gypsum, limestone, basalt and other materials. Additionally, wobbler feeders are used at various stages of the process in mines and stone crushing and screening facilities.

PB® series Pallet Feeders: It consists of nine (9) parts: chassis, chain, pallet, carrier roller, suspension roller, tension table, direction wheel, rim gear and drive group. There are two separate chains on the chassis, independent of each other, and the carrier chains move on the carrier rollers around the direction wheel and rim gear. The pallets are fixed to both chains with bolts. The drive group fixed on the chassis transmits the movement it receives from the electric motor to the pallets via the rim gear. In order to bring the chains to the appropriate working position, the tension table is tensioned until it reaches a sufficient level by means of hydraulic pistons. Hanger rollers support the chains so that the tensioning process can be carried out without difficulty and to prevent the chains from sagging. The pallet feeder carries the product fed on it towards the dumping point via carrier pallets. Thanks to the overlapping structure of the pallets, it carries the product stably without spilling. It is preferred because it provides the opportunity to work at variable transport speeds under changing load conditions and provides significant ease of operation in situations requiring high capacity under difficult conditions. Advantages Transporting moist, sticky and high capacity materials Variable transport speed under variable load conditions It does not require maintenance for a long time with its heavy-duty equipment. Easy spare parts replacement Usage areas Crawler feeders are generally used for emptying the feed hopper in sectors such as quarries, aggregate facilities, power plants, cement facilities, fertilizer facilities, mineral processing facilities, open pit mining and underground mining, and as loading or unloading conveyors in the cement and raw material industry.

No product info found.

No represented companies found.

- BELLİ MAKİNA

TR

TR